|

|

Our Sponsors:

| |

© PTL

2011 - 2012

All Rights Reserved

Skip Navigation Links |

|

||

DR. SINTER® LAB Series; Spark Plasma Sintering Device produced by Metal Processing Systems. Pulsed direct current is driven through a die encased powder sample held under uniaxial load, generating Joule heat. This equipment is capable of producing approximately 50kN force, and temperautres up to approximately 2000 deg. C. This novel technique is an essential tool for reduction of harmful grain growth, due in part to greatly decreased processing time, and high temperature rates (in excess of 100K/min). |

Microwave

Sintering System VIS-300-01a produced by Communications

and Power Industries; completely integrated, computer controlled

system for rapid powder processing/sintering with temperature capability

of up to 2000oC. |

Theta Industries Inc., “Dilamatic II SDP” Dilatometer; primarily used for shrinkage measurements. This device includes a digital data acquisition micrometer, a 1600oC silicon carbide tube furnace, software programmable temperature controller, and analog temperature meter. Dilatometry data is useful in order to compare the effectiveness or efficiency of many novel experimental powder processes. |

|

|

|

| Keyence VHX-600 digital HD CCD microscope with 3-D capability. Equipped with 20 to 200x and 200 to 1000x hand-held or mounted magnification lenses and a tilting stage. Primarily utilized for initlal characterization of samples including color, impurity, average grain size and morphology. | Thermolyne 46200 High temperature muffle furnace; with temperature capability of up to 1600oC. | Labconco "FreeZone 1"; Freeze drying device shown with attached roughing/mechanical pump. Capable of sublimating various solutions, and preserving critical solution mixing states. |

|

|

|

| WAB Tubular Mixer | Bransonic ultrasonic bath device | MTI UV Ozone Cleaner, Model: EQ-PCE-66 |

|

|

|

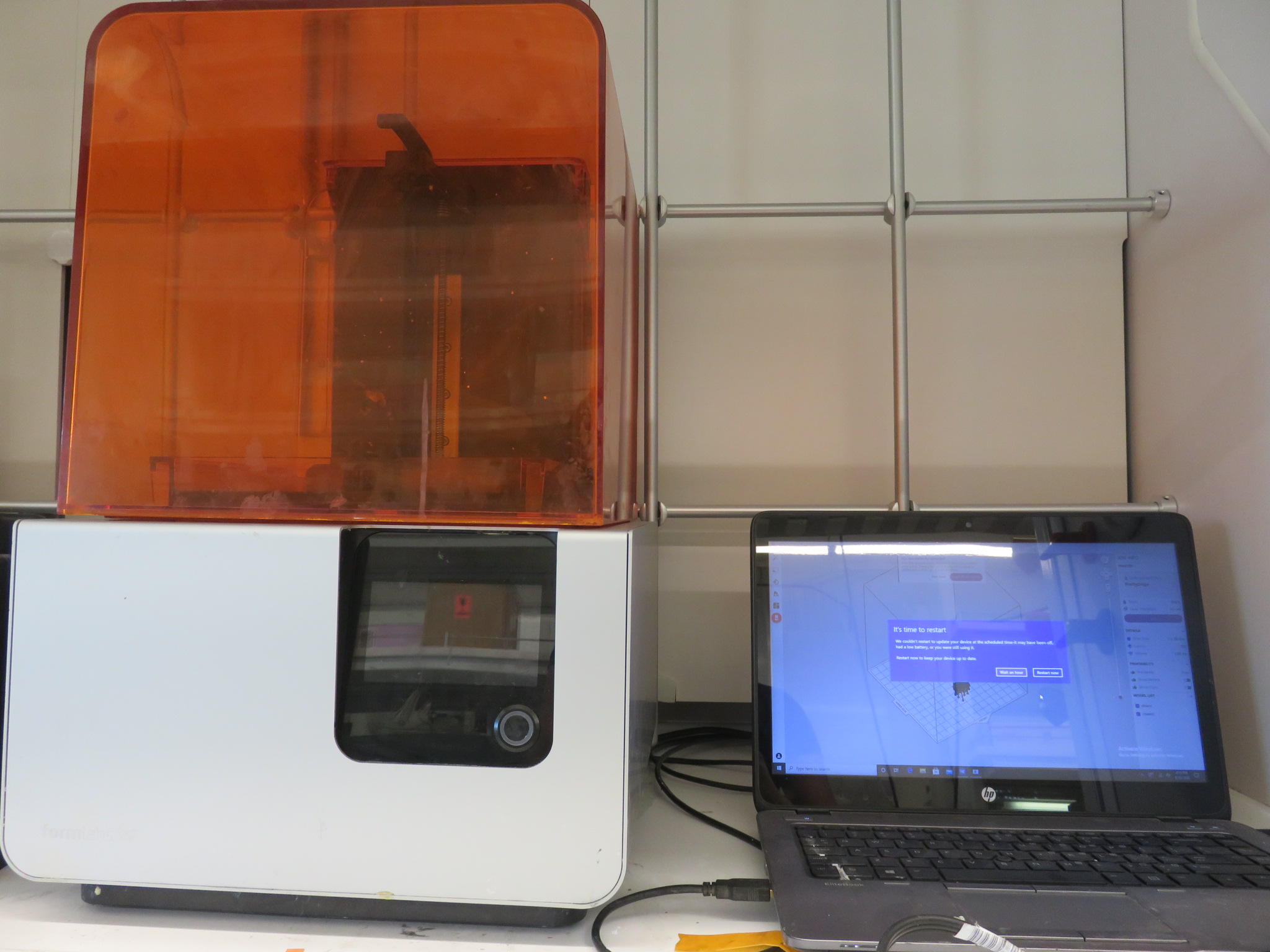

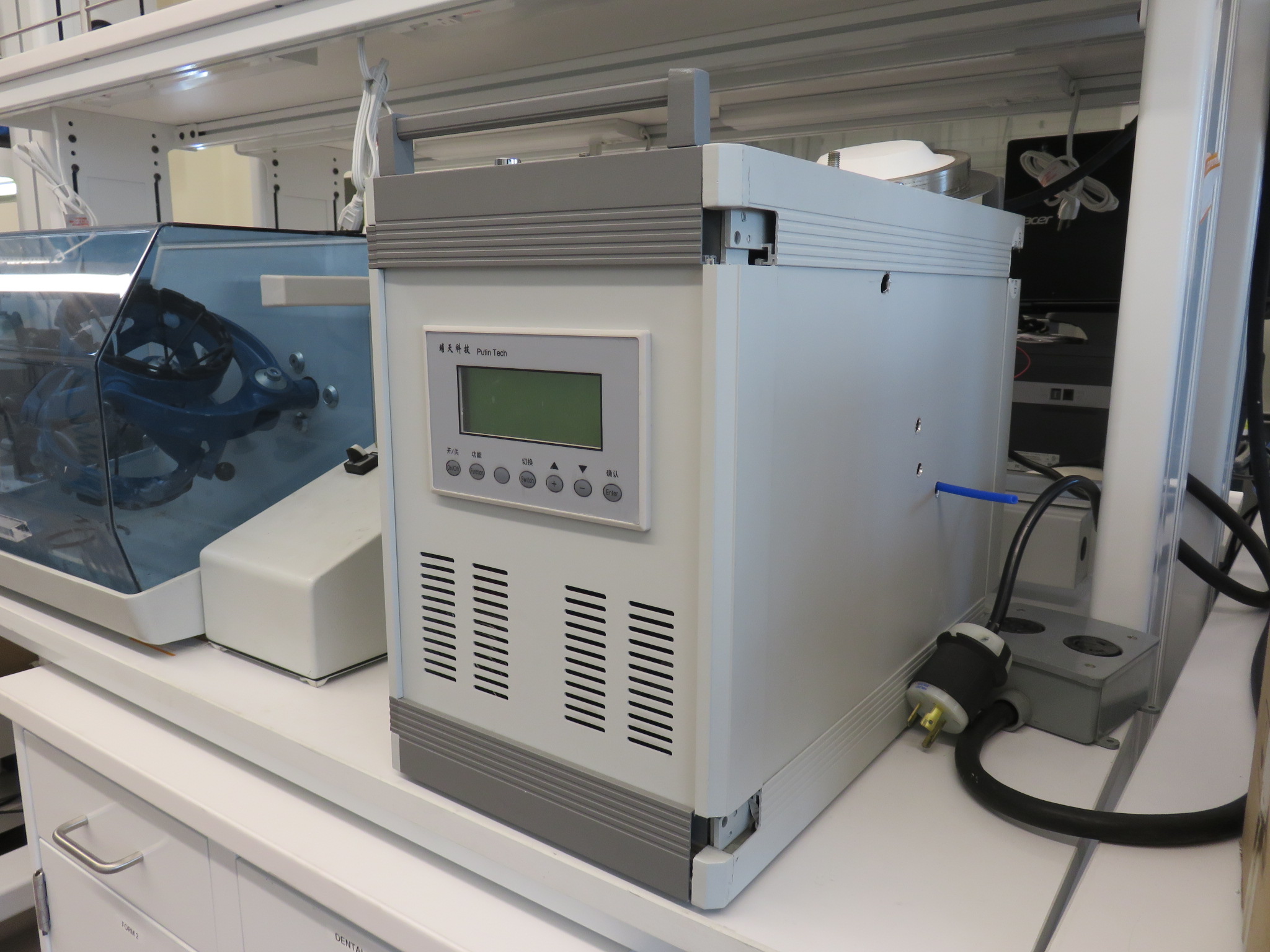

| Microwave Press | Stereolithography 3D printer Formlab 2 | Microwave oven |

|

|

|

| MTI Furnace 1200x | MTI Furnace 1700x; with inert gas capabilities | Circular tube furnace (1500) |

|

|

|

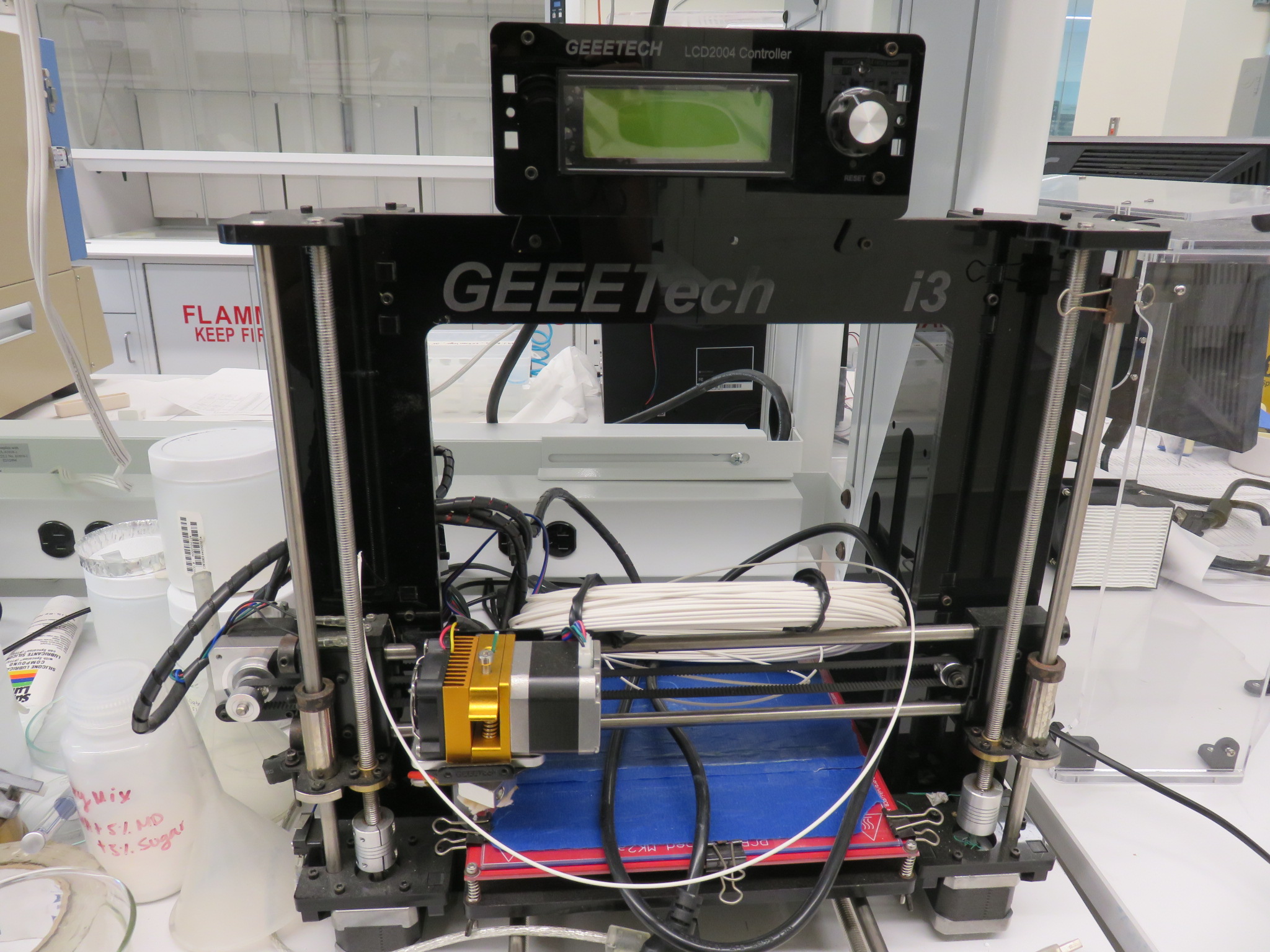

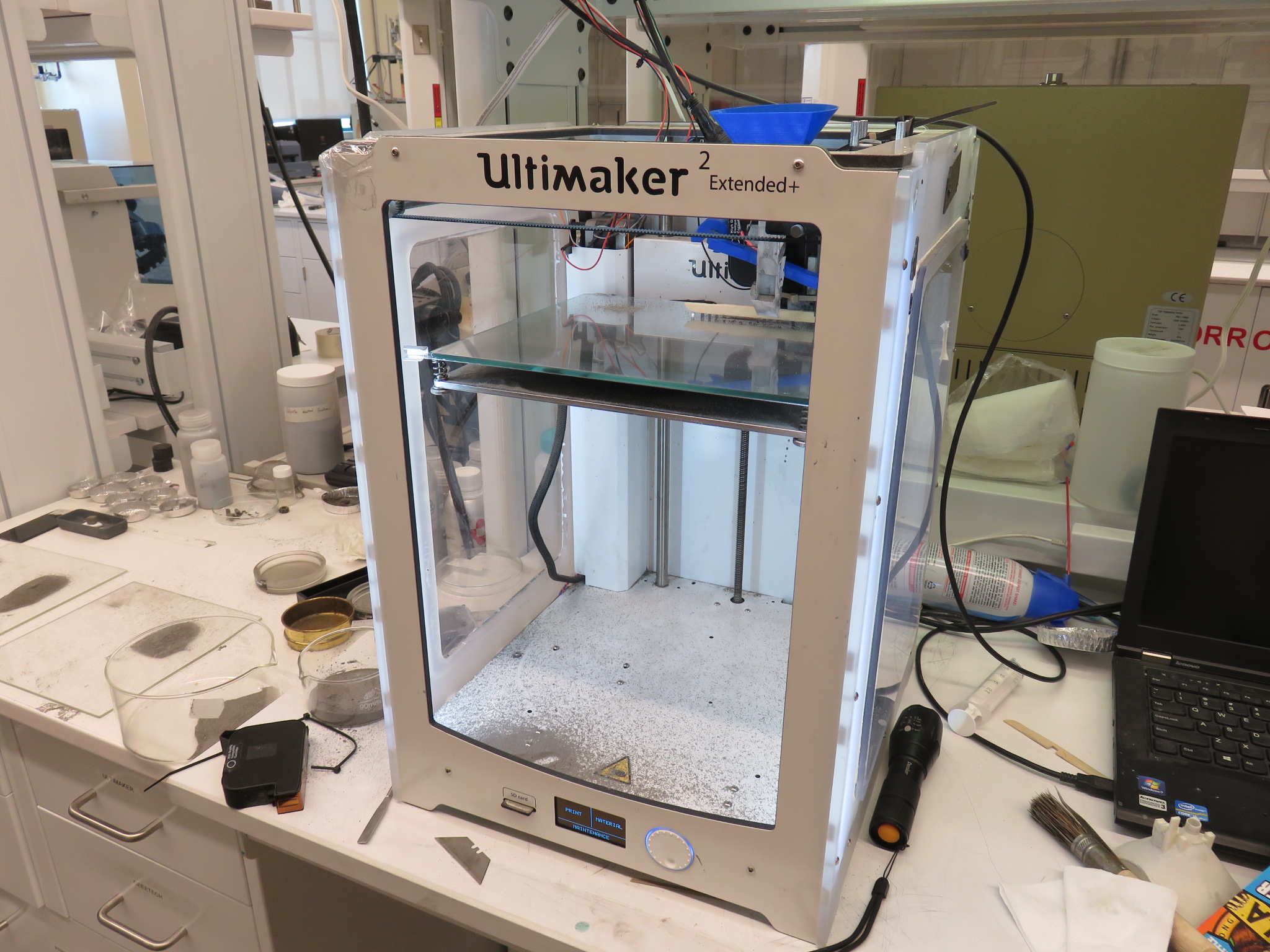

| Printrobot 3D Printer (US) | Geetech 3d printer | 3D printer; Ultimaker 2+ |

|

|

| Furnace with high large volume capability | 3D Binder Jet Zprinter® 350, Z-Corp, Binder Jetting | Stereolithography 3D printer Wanhao duplicator 7 |

|

|

AIP Cold Isostatic Press (CIP); for isostaic powder compaction/green sample preparation. (maximum of 75 kpsi) |

LC-106A, Fritsch Planetary Mono Mill; Planetary ball mill for powder milling processes. | Precision Vacuum Oven and Pump; necessary for rapid evacuation/exsiccation of powder mixtures, green samples and slurries. |

|

|

|

Denton Vacuum Desk IV Cold Sputter Coating device. Bombardment of a sputter target will generate particulate vapor which will condense into very thin, amorphous layers onto available surfaces within the device vacuum chamber. This instrument is primarily utilized for SEM sample preparation. |

Struers Tegra Sample Polishing System | Buehler precision saw, ISOMET 1000 |

"Tinius-Olsen" Universal Testing Machine; This device is utilized for tensile rupture strength (TRS) testing. Compressive and tensile loading data is obtained via rate or force controlled DAQ software and can be exported in Excel executable files. |

In-house prototyping facility managed by Michael Lester; pictured here with the Prototrak VM CNC milling machine. Essential resource for welding, cutting, lathing, machining, prototype and composite material manufacturing. | Quantachrome "MONOSORB MS-16"; Automated Direct Reading Surface Area Analyzer. The MONOSORB measures the quantity of a gas adsorbed on a solid surface, by sensing the change in thermal conductivity of a flowing mixture of an adsorbate and an inert carrier gas, 30% Nitrogen in a Helium balance. |

|

|

|

Branson-Bransonic ultrasonic welding device. Primarily utilized for dispersion of powders in solution. Equipped with 12 various horn configurations and adjustable frequency. |

100,000 PSI, Hydraulic PHI Press | Carver Hydraulic 20 Ton Press; for uniaxial powder compaction/green sample preparation. |

|

|

|

Large Ney Furnace for pre-sintering, binder burnout and conventional powder sintering with a two-stage heating regime control up to 1100oC. |

1 of 3 Small Ney Furnaces; modified by an in-wall fused silica translucent window. This design allows an in-situ monitoring of shape distortions during sintering. This furnace has also been utilized for sinter-forging experiments by mounting it inside the working space of an Instron (universal testing) machine and inserting a pushrod into the furnace working space. | Glove-box with controllable atmosphere (Gasses, Vacuum, etc.). |

|

||

Labconco Protector, chemical fume hood. |

Instron"5982 Universal Testing Machine; Equipped with a 100kN load cell, this device is mainly utilized for low-strain-rate testing. Compressive and tensile loading data is obtained via Bluehill 2 DAQ software package and can be exported in convenient formats, such as Excel or graphic image files (.jpg .bmp etc.). | Micromeritics AccuPyc 1330 Helium pycnometer device. Utilized for volume and theoretical density measurements of powder samples. |

|

|

|

Ohaus analytical balance with 200g capacity readability of 0.1mg and precision of 0.2mg. |

Carter Multi-channel Peristatic Fluid Pumping System; capable of programmed release of up to eight seperate fluid slurries at different flow rates. Utilized for production of functionally graded materials. | Electrophoresis

Power Supply (will generate up to 2000 DC volts.) |

|

||

ATM Sonic Sifter Laboratory model dry sieving instrument. Allows for particle seperation in the sub-sieve range. Equiped with a variety of sieves from 20 - 400 mesh. |

Aerosizer Mach II Particle Size Analyzer; allows the researcher the ability to easily measure in-flight particle size distibution. | Teledyne-Readco rotational mixing device with variable rotary and intensifier speeds. |

Double cone mixing device, capapble of processing large volume powder samples. |

Single speed rotating Jar Mill. | Roll Pelletizer equiped with 1mm pellet rollers and variable speed control. Utilzied for fabrication of granulated powder samples. |

|

||

Paul O. Abbe Inc. fixed speed rotational mill. |

Left to right; BD Clay Adams MHCT II Microhematocrit Centrifuge, Beckman Microfuge 12 Centrifuge, IEC Clinical Centrifuge. Utilized for solution separation processes. | Sequoia-Turner Model 690 Spectrophotometer. Utilized for measuring light intensity as a function of wavelength. |

|

|

|

CM Furnace; primarily used for sintering mutiple specimens simutaneously in required atomosphere (Argon, Hydrogen etc), a 1700oC maximum temperature can be achieved. This furnance provides a possibility to compare the performance of differernt materials under identical sintering conditions. |

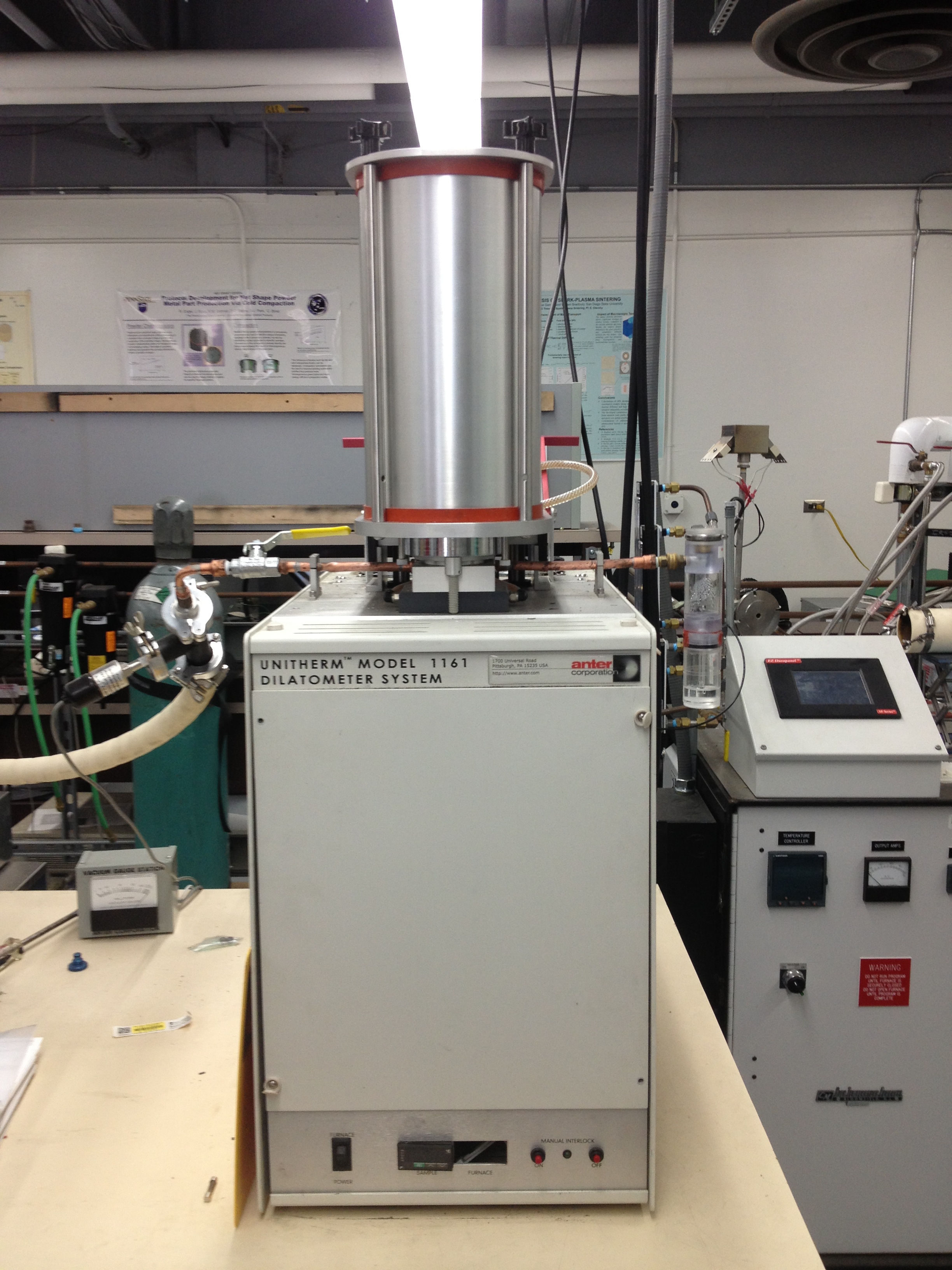

Anter 1161 Dilatometer; primarily used for shrinkage measurements. This device features two dial gauges with digital data acquisition, a 1600oC max temperature tube furnace and software programmable temperature controller. This dillatometer provides the advantage of subjecting two samples to the same sintering conditions for direct comparative analysis. | Nikon Microscope with up to 2000x magnification and integrated image analysis system. |  |

|

TA Instruments STD Q600, Differential Scanning Calorimetry (DSC). |

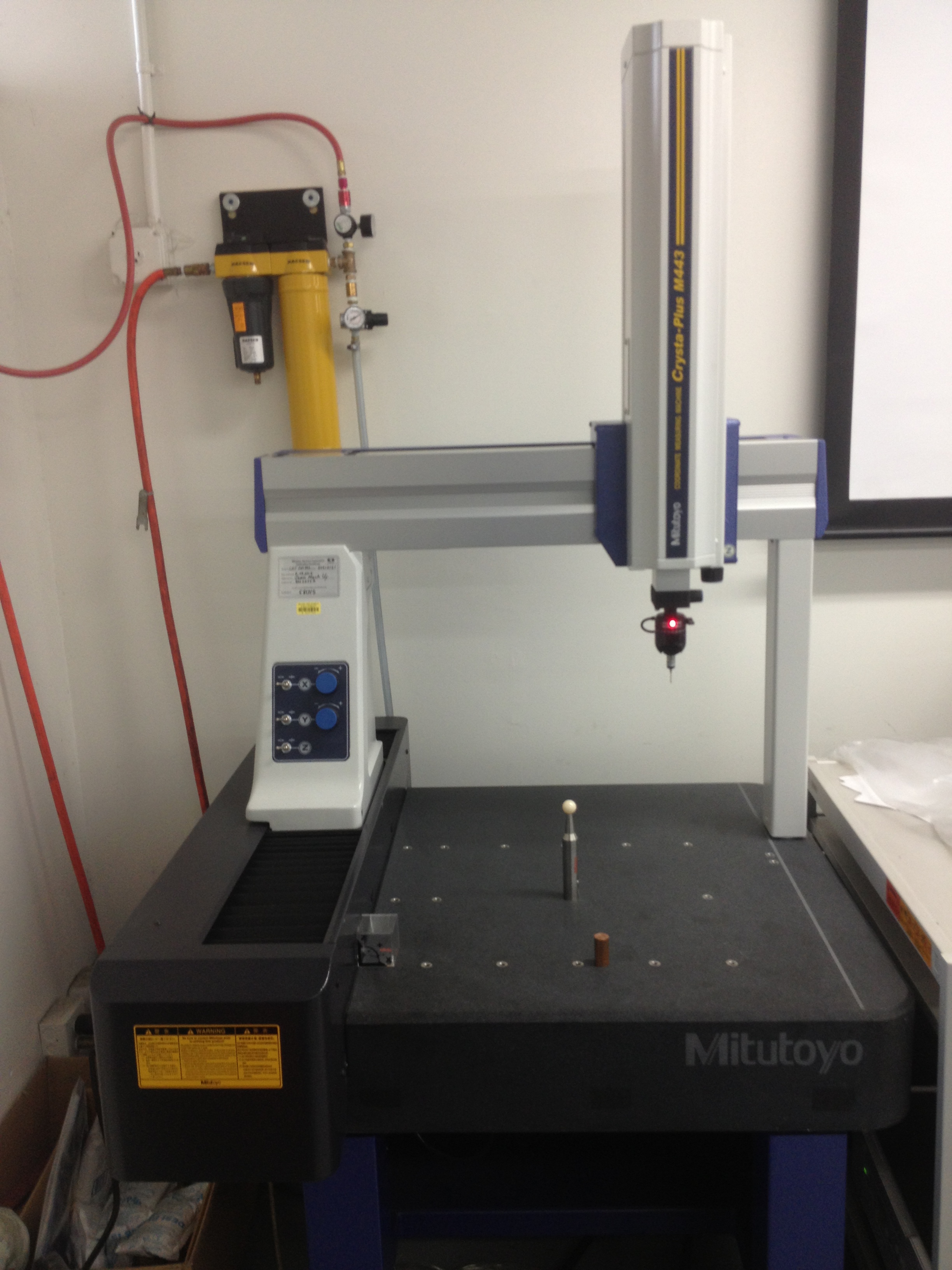

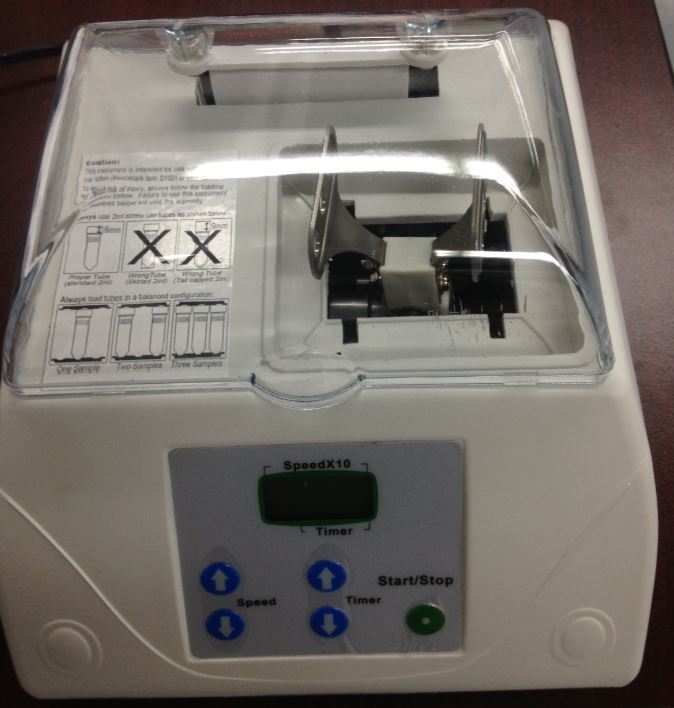

Mitutoyo M443,Cordinate Measuring Machine (CMM); primarily used for quantifying the profile of as sintered specimens. | Benchmark BeadBug Model D1030(E), Microtube Homogenizer. A 2800 to 4000 rpm speed of a 2 ml tube can be achived. |

|

||

| Exone Innovent+ upgraded with ultrasonic recoater that is capable of working with a wider range of powders and simplifies powder change over. | Xact Metal - XM 200C Metal Powder Bed Fusion. |

|

Materials Processing Equipment (Not pictured)

|

Material Characterization Equip (Not pictured)

|

|

The Powder Technology Lab is located at San Diego State University, EIS-222. PTL reserchers have access to a large lab with diverse characterization and powder processing equipment. In addition, computational opportunities with Solidworks, Abaqus Comsol and Matlab are available, as well as access to other engineering lab facilities and an on-campus SEM and TEM characterization lab and X-ray Analysis Lab. Postdoctoral fellows: Thomas Grippi Doctoral Students: Runjiang Jiang, Zackary Skinner, Maryam Ghorbani, Mahlatse Ramaesele Mphahlele and Thato Sharon Tshephe . Masters Students: Shirley Chan |